Moving Optical Tables

Click on the images to get a better view

- For this job, you will need the CROWN Hoist, the two yellow straps, a stainless steel bar (1″ in diameter), 3 long 4″x6″ boards, and two carts (not pictured). Since the hoist’s maximum tong lift is just over 5′, so you can’t flip a table wider than this. The table pictured here is a 4’x12’x12″ and probably weighs close to 1500 lbs. Start by lifting the table up with the hoist, taking off the legs, and laying it down on the three boards.

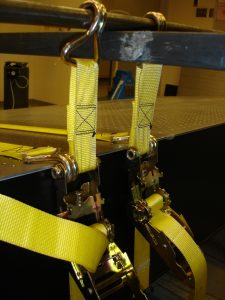

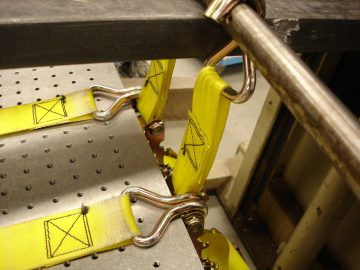

- The next step is to strap the table. Notice the orientation of the crank, and hooks. This is pretty critical and there’s only one way which doesn’t lead to munching the straps or a critical failure when lifting. The assembly is done in situ with the hoist tongs just above the table (see previous pic). The strap spacing is set at around 6″ and determined by the tongs – see next pics. The above picture shows the straps fully engaged (i.e. the table is lifted slightly), and it is very important to slowly engage the straps and check that everything is okay with the straps before proceeding. In particular, keeping the hooks from pinching or munching the straps is key.

- We usually do this with the hoist tongs as close together as possible and centered. The width of the tongs sets the 6″ strap separation.

- Ideally the weight is equally distributed between the two straps.

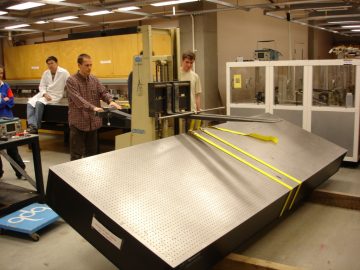

- With the straps secure, you can raise the hoist tongs.

- While carefully driving forward…

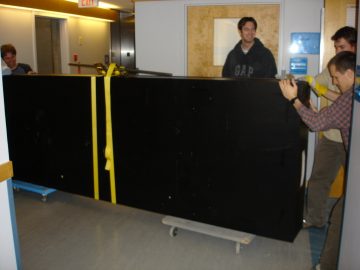

- Once the table is vertical, you can use the palet jack (not pictured) to raise it up off the boards and slide under the carts. This can be done with the hoist in place for safety. Little rubber pads are sometimes used between the 1/4″ stainless skin and the carts to insure the table doesn’t slide around on the carts.

- Pushing the table around inside is fairly safe if you’re careful. Obviously, whenever possible tilt the table back down and roll it on the carts lying down or use the crown hoist which is quite powerful.

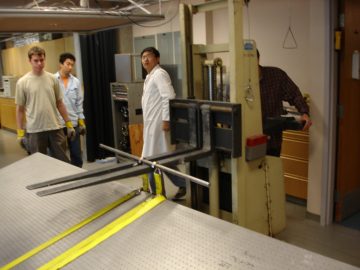

- rounding corners requires some teamwork…

- the cart wheels sometimes need to be kicked into the correct orientation.

- Finish the job by lowering the table to do the final manuvering. Rough positioning can be done with the carts or with the hoist, but final tweaking (0.25″ accuracy with a little practice) is done with the table raised up to the leg level height just before lowering it onto the legs.